Synthetic sleepers | The new generation of sleepers

november 25, 2020Bemo Rail is continuously developing and innovating, by choosing the best, most sustainable and environmentally friendly materials. Our engineering department has researched the possibilities for new materials that are better for the climate, without compromising on quality.

The new generation of sleepers

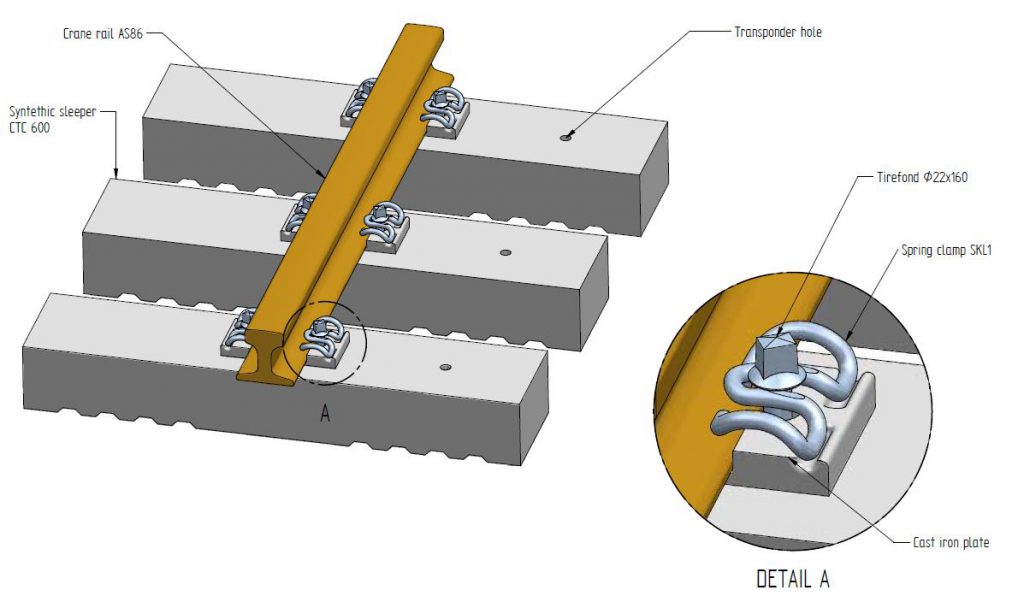

In addition to our regular concrete sleeper, we also offer a new generation of sleepers, a fully synthetic sleeper. The sleepers are made from a recycled material and produced according to a patented technology. We have full control of the production process because it concerns our own production. We use a low temperature process, no injection moulding, but melting and high pressure formation. The emphasis is on the long molecule structure.

Synthetic material is often used for bridges, switches, but also for train tracks, lightrail and industrial applications. The advantage of synthetic material is that the product is strong, durable, lightweight, easy and quick to assemble and completely circular. The price is low (compared to other synthetics), the TOC is low and availability is guaranteed.

Why use synthetic sleepers:

- Fully recycled material

- Own material, full control of input and process

- Patented technology

- Low temperature process. No injection moulding, but melting and high pressure formation.

- Accent on long molecule structure

- High capacity 100,000 pieces and scalable

- Used all over the world

- Resistant to compression load formation

- Toughness, synthetics absorbs energy during load

More information:

For more information, contact Erik de Jong on +31226 42 53 00 or via info@bemorail.nl

Have a look at all our sleepers types.